How A Sand Filter Works

Sand filter used for water treatment

Sand filters are used as a step in the water treatment procedure of water purification.

There are three main types; rapid (gravity) sand filters, upward catamenia sand filters and slow sand filters. All three methods are used extensively in the water industry throughout the earth. The offset two require the use of flocculant chemicals to piece of work effectively while irksome sand filters can produce very high quality water with pathogens removal from 90% to >99% (depending on the strains), taste and odour without the need for chemical aids.[1] Sand filters can, autonomously from being used in water treatment plants, be used for water purification in singular households every bit they use materials which are available for most people.[two]

History [edit]

The history of separation techniques reaches far back, as filter materials were already in use during ancient periods. Rushes and genista plants were used to fill sieving vessels that separated solid and liquid materials. The Egyptians also used porous dirt vessels to filter drinking water, wine and other liquids.[3]

Sand bed filtration concept [edit]

A sand bed filter is a kind of depth filter. Broadly, in that location are two types of filters for separating particulate solids from fluids:

- Surface filters, where particulates are captured on a permeable surface

- Depth filters, where particulates are captured inside a porous body of textile.[4]

In addition, there are passive and agile devices for causing solid-liquid separation such equally settling tanks, self-cleaning screen filters, hydrocyclones and centrifuges.[4]

In that location are several kinds of depth filters, some employing fibrous material and others employing granular materials. Sand bed filters are an example of a granular loose media depth filter. They are usually used to separate pocket-sized amounts (<ten parts per million or <10 g per cubic metre) of fine solids (<100 micrometres) from aqueous solutions.[5] : 302–303 In improver, they are usually used to purify the fluid rather than capture the solids equally a valuable fabric. Therefore they find most of their uses in liquid effluent (wastewater) handling.

Particulate solids capture mechanisms [edit]

Sand bed filters work past providing the particulate solids with many opportunities to be captured on the surface of a sand grain. As fluid flows through the porous sand along a tortuous route, the particulates come close to sand grains. They can be captured by i of several mechanisms:

- Direct collision

- Van der Waals or London force attraction

- Surface charge attraction

- Diffusion[iv]

In addition, particulate solids can be prevented from beingness captured by surface charge repulsion if the surface accuse of the sand is of the same sign (positive or negative) every bit that of the particulate solid. Furthermore, it is possible to dislodge captured particulates although they may exist re-captured at a greater depth inside the bed. Finally, a sand grain that is already contaminated with particulate solids may become more bonny or repel addition particulate solids. This can occur if by adhering to the sand grain the particulate loses surface accuse and becomes attractive to boosted particulates or the opposite and surface charge is retained repelling further particulates from the sand grain.

In some applications it is necessary to pre-treat the effluent flowing into a sand bed to ensure that the particulate solids tin exist captured. This can be achieved by one of several methods:

- Adjusting the surface charge on the particles and the sand past changing the pH

- Coagulation – calculation minor, highly charged cations (aluminium 3+ or calcium 2+ are usually used)

- Flocculation – adding small amounts of charge polymer chains which either class a bridge between the particulate solids (making them bigger) or between the particulate solids and the sand.

Operating regimes [edit]

They can exist operated either with upward flowing fluids or downward flowing fluids the latter being much more usual. For downward flowing devices the fluid can menstruum under pressure or by gravity lonely. Pressure sand bed filters tend to exist used in industrial applications and oft referred to as rapid sand bed filters. Gravity fed units are used in water purification especially drinking water and these filters have found wide use in developing countries (irksome sand filters).

Overall, there are several categories of sand bed filter:

- rapid (gravity) sand filters

- rapid (pressure) sand bed filters

- upflow sand filters

- slow sand filters

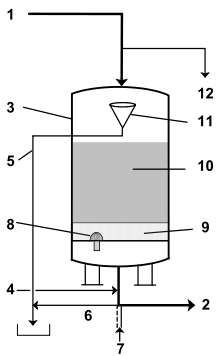

The sketch illustrates the general structure of a rapid force per unit area sand filter. The filter sand takes up near space of the bedroom. Information technology sits either on a nozzle floor or on top of a drainage organization which allows the filtered water to exit. The pre-treated raw water enters the filter chamber on the top, flows through the filter medium and the effluent drains through the drainage arrangement in the lower office. Big process plants have also a organisation implemented to evenly distribute the raw water to the filter. In improver, a distribution system controlling the air flow is usually included. It allows a constant air and water distribution and prevents too high h2o flows in specific areas. A typical grain distribution exits due to the frequent backwashing. Grains with smaller diameter are dominant in the upper role of the sand layer while coarse grain dominates in the lower parts.

Two processes influencing the functionality of a filter are ripening and regeneration.

At the showtime of a new filter run, the filter efficiency increases simultaneously with the number of captured particles in the medium. This procedure is chosen filter ripening. During filter ripening the effluent might non come across quality criteria and must be reinjected at previous steps in the plant.[6] Regeneration methods allow the reuse of the filter medium. Accumulated solids from the filter bed are removed.[6] During backwashing, water (and air) is pumped backwards through the filter system. Backwash h2o may partially be reinjected in front of the filter process and generated sewage needs to be discarded. The backwashing fourth dimension is determined by either the turbidity value behind the filter, which must not exceed a set up threshold, or past the head loss beyond the filter medium, which must too not exceed a certain value.

Rapid pressure level sand bed filter design [edit]

Rapid pressure filter 1=raw water, two=filtered water, iii=tank, 4=inlet flushing water, 5=outlet flushing h2o, 6=retraction line, 7=scavenging air, eight=injector, nine=supporting layer, 10=filter sand, 11=flushing funnel, 12=ventilation

Smaller sand grains provide more surface area and therefore a higher decontamination of the inlet h2o, merely information technology also requires more pumping free energy to drive the fluid through the bed. A compromise is that near rapid pressure sand bed filters use grains in the range 0.6 to 1.ii mm although for specialist applications other sizes may be specified. Larger feed particles (>100 micrometres) will tend to block the pores of the bed and turn it into a surface filter that blinds rapidly. Larger sand grains can be used to overcome this problem, only if meaning amounts of big solids are in the feed they need to exist removed upstream of the sand bed filter by a procedure such as settling.[5] : 302–303

The depth of the sand bed is recommended to be around 0.half dozen–1.8 chiliad (2–6 ft) regardless of the awarding. This is linked to the maximum throughput discussed below.[5] : 302–303

Guidance on the blueprint of rapid sand bed filters suggests that they should be operated with a maximum flow charge per unit of 9 m3/10002/hr (220 U.s.a. gal/ft2/hour).[7] Using the required throughput and the maximum flow charge per unit, the required area of the bed can be calculated.

The final central design point is to be certain that the fluid is properly distributed across the bed and that there are no preferred fluid paths where the sand may be washed away and the filter be compromised.

Rapid pressure sand bed filters are typically operated with a feed pressure of 2 to 5 bar(a) (28 to 70 psi(a)). The pressure driblet across a make clean sand bed is usually very depression. Information technology builds as particulate solids are captured on the bed. Particulate solids are not captured uniformly with depth, more are captured higher upwards with bed with the concentration gradient decaying exponentially.[five] : 302–303

This filter type will capture particles down to very small sizes, and does not take a true cut off size below which particles volition always pass. The shape of the filter particle size-efficiency curve is a U-shape with loftier rates of particle capture for the smallest and largest particles with a dip in between for mid-sized particles.[vii]

The build-up of particulate solids causes an increase in the pressure lost across the bed for a given flow rate. For a gravity fed bed when the pressure available is constant, the catamenia rate will autumn. When the pressure loss or flow is unacceptable and the filter is not working effectively any longer, the bed is backwashed to remove the accumulated particles. For a pressurized rapid sand bed filter this occurs when the force per unit area drop is effectually 0.5 bar. The backwash fluid is pumped backwards through the bed until it is fluidized and has expanded by up to nearly 30% (the sand grains get-go to mix and as they rub together they bulldoze off the particulate solids). The smaller particulate solids are washed away with the backwash fluid and captured unremarkably in a settling tank. The fluid flow required to fluidize the bed is typically 3 to ten m3/grand2/hr but not run for long (a few minutes).[5] : 224–235 Small amounts of sand can be lost in the backwashing process and the bed may need to be topped upward periodically.

Slow sand filter blueprint [edit]

As the championship indicates, the speed of filtration is changed in the slow sand filter, notwithstanding, the biggest difference between slow and rapid sand filter, is that the top layer of sand is biologically active, as microbial communities are introduced to the organisation. The recommended and usual depth of the filter is 0.9 to 1.5 meters. Microbial layer is formed within 10–20 days from the start of the operation. During the process of filtration, raw water can percolate through the porous sand medium, stopping and trapping organic material, bacteria, viruses and cysts such as Giardia and Cryptosporidium. The regeneration procedure for wearisome sand filters is chosen scraping and is used to mechanically remove the dried out particles on the filter. All the same, this process can also be done nether water, depending on the private system. Another limiting factor for the water beingness treated is turbidity, which is for slow sand filters defined to be 10 NTU (Nephelometric Turbidity Units). Slow sand filters are a proficient option for limited budget operations every bit the filtration is not using any chemicals and requires niggling or no mechanical aid. Yet, because of a continuous growing population in communities, ho-hum sand filters are being replaced for rapid sand filters, mostly due to the running period length.

Characteristics of rapid and dull sand filters[6] [edit]

| Characteristics | Rapid sand filter | Slow sand filter |

|---|---|---|

| Filtration rate [thousand/h] | five–15 | 0.08–0.25 |

| Media constructive size [mm] | 0.5–1.ii | 0.fifteen–0.thirty |

| Bed depth [m] | 0.6–1.9 | 0.9–one.5 |

| Run length | 1–4 days | 1–half dozen months |

| Ripening period | 15 min – 2 h | Several days |

| Regeneration method | Backwashing | Scraping |

| Maximum raw-water turbidity | Unlimited with proper pretreatment | 10 NTU |

Mixed bed filters [edit]

Filters can be synthetic with unlike layers, chosen mixed bed filters. Sand is a common filter material, but anthracite, granular activated carbon (GAC), garnet and ilmenite are likewise common filter materials. Anthracite is a harder cloth and has less volatile compared to other dress-down. Ilmenite and garnet are heavy compared to sand. Garnet consists several minerals, causing a shifting red colour. Ilmenite is an oxide of atomic number 26 and titanium. GAC can exist used in the process of adsorption and filtration at the same time. These materials can be used both alone, or combined with other media. Dissimilar combinations requite dissimilar filter nomenclature. Monomedia is a one layered filter, ordinarily consisting of sand and is today replaced by newer engineering. Deep-bed monomedia is also a one layered filter which consist of either anthracite or GAC. The deep-bed monomedia filter is used when there is a consistent water quality and this gives a longer run time. Dual media (ii layered) frequently contain a sand layer in the bottom with an anthracite or GAC layer on top. Trimedia or mixed media is a filter with three layers. Trimedia ofttimes accept garnet or ilmenite in the bottom layer, sand in the heart and anthracite at the top.

Uses in h2o handling [edit]

All of these methods are used extensively in the water industry throughout the world. The commencement three in the list above crave the use of flocculant chemicals to work effectively. Dull sand filters produce high-quality water without the use of chemical aids.

Passing flocculated water through a rapid gravity sand filter strains out the floc and the particles trapped within it, reducing numbers of bacteria and removing most of the solids. The medium of the filter is sand of varying grades. Where taste and odor may be a trouble (organoleptic impacts), the sand filter may include a layer of activated carbon to remove such taste and odor.

Sand filters become clogged with floc or bioclogged after a period in use. Ho-hum sand filters are and then scraped (see above) while rapid sand filters are backwashed or force per unit area washed to remove the floc. This backwash h2o is run into settling tanks so that the floc can settle out and it is then tending of every bit waste textile. The supernatant water is and then run dorsum into the treatment process or disposed of every bit a waste material-water stream. In some countries, the sludge may exist used equally a soil conditioner. Inadequate filter maintenance has been the crusade of occasional drinking water contamination.

Sand filters are occasionally used in the sewage treatment as a final polishing phase. In these filters the sand traps residual suspended cloth and leaner and provides a physical matrix for bacterial decomposition of nitrogenous material, including ammonia and nitrates, into nitrogen gas.

Sand filters are one of the virtually useful treatment processes as the filtering process (especially with slow sand filtration) combines within itself many of the purification functions.[8]

Challenges in the awarding process [edit]

In the procedure of water treatment, 1 should be aware of certain factors that might crusade serious problems if not treated properly. Aforementioned processes such every bit filter ripening and backwashing influence not only the h2o quality only too the time needed for the total handling. Backwashing reduces besides the volume of the effluent. If a certain amount of water has to be delivered to due east.grand. a community, this water loss needs to be considered. In addition, backwashing waste needs to exist treated or properly discarded. From the chemical perspective, varying raw h2o qualities and changes in the temperature effect, already at the archway to the constitute, the efficiency of the treatment process.

Considerable doubt is involved regarding models used to construct sand filters. This is due to mathematical assumptions that accept to be made such equally all grains being spherical. The spherical shape affects the interpretation of the size since the diameter is different for spherical and non-spherical grains. The packing of the grains inside the bed is also dependent on the shape of the grains. This and then affects the porosity and hydraulic menses.[6]

Encounter also [edit]

- American Water Works Association

- Water treatment

- Water purification

- Jewell water filter

References [edit]

- ^ "Slow Sand Filtration" (PDF). National Drinking Water Clearinghouse.

- ^ "Household Sand Filters for Arsenic Removal" (PDF). EAWAG.

- ^ Anlauf, Harald (2003). "Mechanische Fest/Flüssig-Trennungim Wandel der Zeit". Chemie Ingenieur Technik. 75 (10): 1460–1463. doi:10.1002/cite.200303283.

- ^ a b c A. Rushton, A. Southward. Ward, R. M. Holdich (1996). Introduction to Solid-Liquid Filtration and Separation Technology. Wiley VCH. ISBN 978-3-527-28613-three

- ^ a b c d e Coulson, J. K.; Richardson, J. F.; Backhurst, J. R., Harker, J. H. (1991). Chemical Applied science. Vol.two, fourth ed. ISBN 0-7506-2942-eight.

- ^ a b c d Crittenden, John C.; Trussell, R. Rhodes; Hand, David W.; Howe, Kerry J.; Tchobanoglous, George (2012). MWH's h2o treatment: principles and pattern (3rd ed.). Hoboken, N.J.: John Wiley & Sons. ISBN9780470405390.

- ^ a b M. J. Ives (1990). "Deep Bed Filtration". Chap. eleven of Solid-Liquid Separation, 3rd ed., L. Svarovsky (ed). Butterworths. ISBN 0-408-03765-ii

- ^ Huisman, L.; Wood, Westward. E. (1974). Slow sand filtration. Geneva: World Wellness Arrangement. ISBN978-9241540377.

How A Sand Filter Works,

Source: https://en.wikipedia.org/wiki/Sand_filter

Posted by: gutierrezforood.blogspot.com

0 Response to "How A Sand Filter Works"

Post a Comment